MSS Case September: Fire in engine room

It was winter and the vessel, a bulk carrier, arrived at the discharge port to unload a cargo of steel pipes. It had recently undergone a major engine overhaul.

In port, a port state inspection was carried out and 13 deficiencies were identified, with some related to firefighting equipment availability, gaskets, valves, and general tidiness.

The vessel departed two days later and sailed in ballast in the North Atlantic towards the next port. The weather on departure was reported as NW 8 winds, 4-6 metre seas, -8°C temperature, and moderate icing. The vessel rolled and pitched in the heavy weather. At 05.55 the fire alarm sounded in the engine room. The Second Engineer went to the engine room and saw fire coming from the main engine in the area of cylinders 8 and 9.

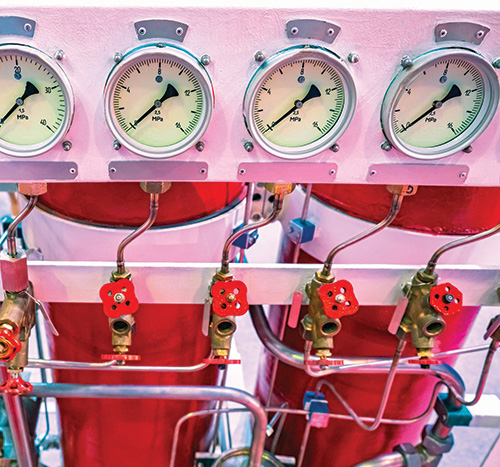

The crew was assembled on the poop deck, and firefighting and lifesaving preparations were initiated. The main engine was stopped by the Second Engineer, using the emergency stop in the engine control room. The Chief Engineer observed fuel spraying from the fuel booster unit’s forward end, and took action to stop the pumps, and close the valves. Attempts to extinguish the fire were unsuccessful. Because of the vessel rolling, fuel which had accumulated on the upper engine room deck spilled onto the top of the main engine and hot exhaust. The fire spread to multiple cylinders, and the crew evacuated the engine room, and the CO2 system was released. However, the system did not work as intended as some of the piping was in bad condition and not all the bottles were released.

An SOS signal was transmitted by the Master which was acknowledge by the coast guard. The Master ordered the crew to abandon ship, which was carried out successfully without any injuries. A coast guard vessel arrived the following day and connected towing lines. Another tug also arrived to assist. It was discovered that a fracture had occurred in a small pipe (approximately 4mm diameter) connected to a shut-off valve and gauge/pressure transmitter unit. Fuel then leaked from the fractured pipe onto the main engine, leading to a fire in the engine room. Ignition was likely due to contact with the hot engine cylinder exhaust manifold.

Repairing the vessel was costly and took three months as all the electrical cabling, insulation, and firefighting equipment in the engine room, in addition to the fuel booster unit, had to be replaced. Cleaning the engine room was a difficult and complicated process.

Questions

When discussing this case please consider that the actions taken at the time made sense for all involved. Do not only judge but also ask why you think these actions were taken and could this happen on your vessel?

- What were the immediate causes of this accident?

- Is there a risk that this accident could happen on

our vessel? - Why do you think cracks had developed on the

pipe? - When a section of pipe is replaced is the entire pipe

inspected and will the pipe be pressure tested after

work has been carried out? - What are our procedures for keeping the engine

room tidy?

The Swedish Club: Monthly Safety Scenario | September 2024 2 - Are our procedures for the fire-extinguishing

system sufficient? - Do we inspect the insulation in the engine room?

- How do we ensure that insulation is adequate in

the engine room?

- When maintenance has been completed do we

inspect that the insulation is in place and not

contaminated? - How often do we inspect the CO2 system and are

all engine crew trained on how to operate it? - How often do we have fire drills in the engine

room, as this is generally where fires start? - Are our firefighting drills effective enough to

address the problems in this case? - Do our procedures make sense to the work we

actually do? - What sections of our SMS were breached, if

any and is our SMS sufficient to prevent this

accident? - If procedures were breached, why do you think

this was the case? - What can we learn?

Download the case as PDF

MSS Case September: Fire in engine room

It was winter and the vessel, a bulk carrier, arrived at the discharge port to unload a cargo of steel pipes. It had recently undergone a major engine overhaul.

For more Loss Prevention information, please contact:

Joakim Enström, Loss Prevention Officer

E-mail: joakim.enstrom@swedishclub.com

Each month, the Club’s Loss Prevention team issues a new safety scenario to assist members in their efforts to comply with international safety regulations and follow best practices.